In recent years, digital transformation has reshaped various sectors, ushering in profound changes that have impacted how businesses operate, engage with customers, and deliver value. Traditional industries, such as manufacturing, retail, agriculture, and logistics, are among the sectors that have felt the effects of this digital shift. The transformation is not just about the adoption of new technologies but about how these industries adapt to the evolving demands of the market, enhance productivity, and future-proof their operations. In this article, we will explore the impact of digital transformation on traditional industries and how it is altering the landscape for businesses and workers alike.

Defining Digital Transformation

Digital transformation refers to the integration of digital technologies into all aspects of a business, fundamentally changing how it operates and delivers value to customers. It goes beyond just using new tools or software—it involves a deep shift in culture, business models, and strategies. For traditional industries, digital transformation often means leveraging technologies such as cloud computing, artificial intelligence (AI), big data analytics, the Internet of Things (IoT), automation, and more to streamline operations, increase efficiency, and improve customer experiences.

For example, manufacturing companies are incorporating IoT devices to track and monitor equipment, predict failures before they occur, and optimize production schedules. Retailers are embracing e-commerce platforms and using data analytics to understand consumer behavior, improve inventory management, and enhance personalization. The common thread across these industries is that digital technologies are helping businesses stay competitive in an increasingly technology-driven world.

Digital Transformation in Manufacturing

Manufacturing, one of the most traditional industries, has seen the most significant impact from digital transformation. The advent of Industry 4.0, characterized by the integration of smart technologies, has revolutionized production processes. With the use of IoT devices, machines can now communicate with each other, allowing for real-time data collection and analysis. This has led to significant improvements in productivity, as manufacturers can now predict maintenance needs, reduce downtime, and ensure optimal equipment performance.

Another major advancement in manufacturing has been the rise of automation and robotics. Robotic systems can handle repetitive tasks with precision and speed, reducing the need for human intervention in mundane processes. This not only enhances efficiency but also improves workplace safety by performing dangerous tasks. Additionally, the use of 3D printing and advanced manufacturing techniques has enabled the creation of custom products on demand, reducing waste and improving flexibility in production lines.

While digital transformation in manufacturing has led to greater operational efficiencies, it has also posed challenges. Traditional manufacturing workers need to adapt to new technologies, requiring retraining and upskilling. The automation of certain jobs also raises concerns about job displacement, although many experts believe that the growth of new technology-focused roles will compensate for these losses.

The Impact on Retail: E-Commerce and Data Analytics

Retail, another traditional industry, has undergone a profound transformation with the rise of e-commerce and digital tools that enhance customer engagement. The shift toward online shopping has been accelerated by the pandemic, and businesses are now focusing on building seamless omnichannel experiences that integrate both online and offline interactions. Digital transformation in retail includes everything from the use of mobile apps and e-commerce websites to personalized recommendations powered by machine learning algorithms.

Data analytics plays a crucial role in the retail transformation. By gathering data from customer interactions, companies can gain valuable insights into consumer preferences, behavior, and purchasing patterns. This allows businesses to offer personalized marketing, improve inventory management, and predict future demand with more accuracy. Retailers can also leverage social media platforms and digital marketing techniques to engage with their customers in innovative ways.

However, this digital transformation also presents challenges for traditional brick-and-mortar retailers. The rise of e-commerce giants like Amazon has forced small and medium-sized businesses to rethink their strategies, shifting from a focus on physical stores to a more robust digital presence. The competition is fierce, and companies that fail to embrace digital transformation risk falling behind in an increasingly digital-first world.

Agriculture: Smart Farming and Sustainability

Agriculture, one of the oldest industries, has also benefited from digital transformation, leading to more sustainable and efficient farming practices. Digital tools such as sensors, drones, and AI are being used to monitor soil health, weather conditions, and crop growth. This allows farmers to make data-driven decisions that improve yields, reduce waste, and minimize the use of water, fertilizers, and pesticides.

For example, precision agriculture techniques are transforming how crops are planted, irrigated, and harvested. Drones equipped with cameras and sensors can survey vast expanses of farmland, providing real-time information about crop conditions. AI systems can analyze this data to make recommendations for optimal planting times, irrigation schedules, and pest control measures. This not only boosts productivity but also promotes environmental sustainability by reducing the overuse of resources.

Digital transformation in agriculture also opens up new possibilities for supply chain management. Blockchain technology is being explored to track the origin of food products, ensuring transparency and safety. Additionally, e-commerce platforms are allowing farmers to sell directly to consumers, bypassing traditional middlemen and increasing profitability. While the digital shift brings opportunities for efficiency and growth, challenges such as the high cost of technology adoption and the need for technical expertise persist.

The Logistics and Supply Chain Revolution

Logistics and supply chain management have also been transformed by digital technologies. The use of big data, AI, and machine learning has made it possible to optimize routes, reduce transportation costs, and improve delivery times. GPS tracking and real-time data sharing allow companies to monitor shipments, anticipate delays, and improve inventory management.

One of the most significant changes in logistics has been the development of autonomous vehicles, drones, and robots. These technologies are expected to revolutionize last-mile delivery, reducing labor costs and speeding up the delivery process. For instance, autonomous trucks can transport goods across long distances without human drivers, while drones can deliver small packages to remote areas within hours.

However, digital transformation in logistics is not without its challenges. Traditional logistics companies must invest heavily in new technologies and infrastructure, which can be a significant financial burden. Additionally, the widespread adoption of autonomous vehicles raises regulatory and safety concerns that need to be addressed before these innovations can become mainstream.

The Role of Digital Transformation in Workforce Transformation

As traditional industries undergo digital transformation, the workforce is experiencing a profound shift. The demand for workers with digital skills has skyrocketed, as companies require employees who can manage and operate advanced technologies. Traditional job roles are evolving, with many tasks becoming automated, while new roles in data analysis, AI, cybersecurity, and digital marketing are emerging.

Workers in industries such as manufacturing and retail must embrace lifelong learning and upskilling to remain competitive in the digital economy. Governments, educational institutions, and private companies must collaborate to ensure that the workforce is equipped with the skills needed for the future. This includes providing training programs, reskilling initiatives, and access to online resources that enable workers to adapt to the rapidly changing job market.

However, the transition to a more digital workforce is not without its challenges. Older workers may find it difficult to adapt to new technologies, and there are concerns about job displacement as automation replaces certain tasks. While digital transformation creates new job opportunities, it is essential to manage this transition carefully to avoid exacerbating inequality and unemployment.

Conclusion: The Path Forward for Traditional Industries

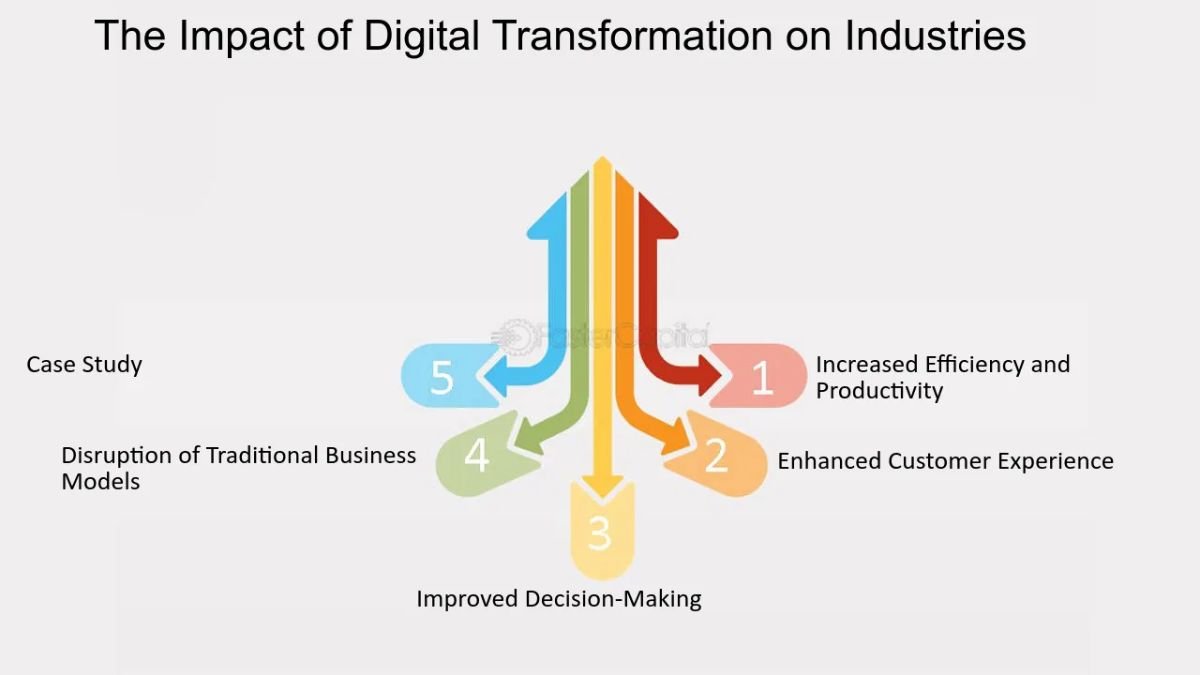

The impact of digital transformation on traditional industries is undeniable. Businesses across sectors are leveraging new technologies to streamline operations, enhance customer experiences, and boost productivity. While the benefits are clear, the challenges are equally significant. Traditional industries must not only adopt new technologies but also adapt their business models, workforce strategies, and customer engagement methods.

For digital transformation to be successful, industries must focus on collaboration, continuous learning, and investment in innovation. The future will likely see greater integration of AI, automation, and data analytics across traditional industries, leading to smarter, more efficient, and more sustainable practices.

As industries navigate this digital shift, the key to success will be maintaining a balance between embracing innovation and preserving the core values that have driven these industries for decades. The businesses that can adapt and evolve will be better positioned to thrive in the digital age, while those that resist change risk being left behind.